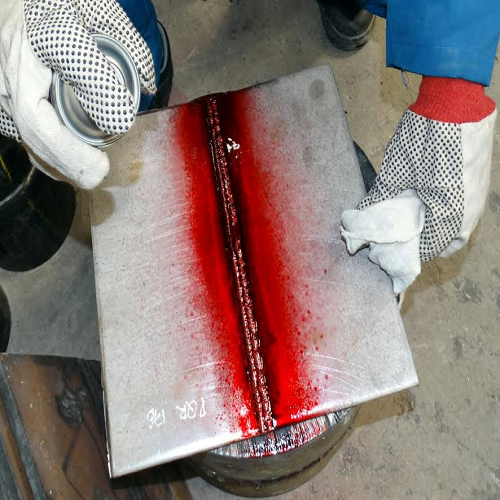

With the support of talented professionals, we are involved in providing highly effective Welding MPI And Visual Testing Service to our prestigious clients. The testing services offered by us are rendered professionally in compliance with the quality standards of the industry. Also, this testing service is available to us in many types at pocket-friendly rates.

Being a leader in the industry, we are engaged in providing a premium quality array of Ferrite Testing Service. Executed beneath the assistance of our experienced employees, these testing services are admired in the market. Additionally, we offer customized testing solutions for all the needs of clients.

Positive Material Identification Testing Services (PMI) applications range from construction steel to surgical instruments, from metal scrap to aerospace equipment. The range is enormous, but we have a solution for your PMI testing needs.

We have reached the pinnacle of success and earned a reputed name by offering a high-quality range of PAUT UT Inspection And Testing Service. The provided inspection and testing service are rendered using advanced technology. Owing to its flawless execution, and perfect work, this inspection and testing service is valued by our honored clients.

We are engaged in offering an optimum quality array of Non Destructive Metal Testing Service for our esteemed customers. Our team also can handle extreme time constraints. Offered array of testing service is rendered under the direction of experts with following the industry quality norms.

Through regular research and development, we are offering an exclusive collection of Standard Penetration Test Service. These services are rendered as per the client's demand. In addition to this, offered testing services are appreciated due to their reasonable prices, and perfect execution.

With the constant support of the professionals, we are offering an extensive array of Penetrate Testing Service. These are rendered as per the client's demands. In addition to this, with the use of modern technology, we create the result for our customers.

To furnish the diverse requirements of clients, we are engaged in offering Ultrasonic Testing Services. These services are rendered using top grade inputs as per set industry values. In addition to this, these are offered at pocket-friendly prices to attain high customer satisfaction.

Due to our expertise and patron-focused approach, we are divinely betrothed in offering to our customer's Trade Tests Services. These provided services are offered by adroit workers. In addition to this, offered trade tests services are rendered at very reasonable rates.

Hardness is a characteristic that applies to a range of materials metals and nonmetals alike and is defined as the resistance of the material to deformation, penetration, scratching, or other physical force. Element's experts measure hardness according to the requirements of the material and its applications, with equipment precisely calibrated to the appropriate hardness scales. The straightforward, timely, and relatively non-destruction nature of hardness testing make it one of the most popular characteristics for engineers interested in materials selection, lot verification testing, the evaluation of material processing, or the comparison of hardness values across multiple material samples. In addition, hardness values can typically be closely correlated with other material properties, such as tensile strength. Macrohardness and Microhardness Testing. Element’s expertise in static deformation hardness methods include both macrohardness (applied loads of more than 1 kg) and microhardness (applied loads of less than 1 kg) in accordance with a wide range of industry standards, most of which call for the use of an indenter of known geometry and mass which is forced into the material’s surface. The amount of force applied along with the depth of the indentation is recorded and used to calculate the appropriate hardness value for a given point on the sample. On-site Hardness Measurements and Portable Hardness. As part of our On-site Metallographic Analysis, we use portable versions of hardness testing to make on-site hardness measurements on large installations or equipment that are either impossible or impractical to ship to a laboratory. We carry out on-site hardness measurements with the following methods: Element can prepare the surface for each of the above methods and advise you on the most suitable method for your specific project needs. With global access to a team of multidisciplinary engineers and the advanced testing equipment, our hardness measurement services offer the portability, flexibility and high performance for on-site metals verification.

Hardness Testing (ASTM E10 and ISO 6506-1) is the oldest hardness method still in common use. The Brinell instrument employs a larger indentor ball (typically 10mm in diameter) and a much higher load (up to 3,000 kgf) than most other hardness test methods. The larger indenter helps ensure that hardness readings are not adversely affected by small surface flaws. Because of this, Brinell hardness testing is frequently used on rough materials with a large number of surface imperfections, such as castings and forgings. Rockwell hardness testing (ASTM E18 and ISO 6508-1) is generally considered to be the most popular and accurate of all hardness methods. Using a ball or cone shaped indentor, Rockwell hardness is used on metals of all types, except for any material with an irregular structure or surface variations that might influence test results. The Rockwell method, which is detailed in ASTM E18 and ISO 6508-1, involves the use of a diamond indenter to apply a smaller preload on the material. This preload breaks through the material’s surface to eliminate the effects of any surface treatments. After the preload, the major load is applied to complete the test. Knoop and Vickers (ASTM E384) are the two most common scales of microhardness testing. These tests use light loads and small indenters, making them ideal for small samples, very thin materials, surface coatings, or for evaluating the case hardness of a material through a series of indentations that create a hardness profile. In accordance with ASTM E384, the Vickers hardness method utilizes a pyramid-shaped diamond indenter. In Knoop microhardness, the indenter is rhombic-pyramid-shaped for longer, shallower indentations.

For cater the needs of clients, we are engaged in offering Welding Consumable Batch Testing Service. After rendering, our team experts check these welding consumable batch testing services to fulfill the requirements of clients. Moreover, we offer this testing service to our clients at market leading prices

As per the requirements of the patrons, we are presenting the best quality array of Liquid Penetrate Testing Service to our prestigious clients. This testing service is available with various options. Moreover, we believe in offering complete satisfaction to the clients and for this, we provide testing service as per client need.

202, Reshmi Plaza, Vasai Railway Station Rd, near Shiv Sena Office, Oppo, E, Samarth Krupa Nagar, Vasai East, Vasai-Virar, Maharashtra 401202